No longer will sites need to have in house experts in various programming languages. Drag&bot is a revolutionary piece of software that allows various robot brands to be programmed on one easy to use software package. Drag&bot supports a variety of different robots, almost all grippers and force sensors and the most common image processing systems and communication interfaces.

Robot Use Cases

See some examples of drag&bot in action, click the button below to be redirected to the manufacturer’s page.

It’s that simple. Set up a robot in 5 easy steps.

Step 1: Connect hardware

Each robot requires a commercially available, powerful PC on which the drag&bot software is executed. The relevant hardware is connected to this industrial PC, which is installed in the robot cell, via Ethernet cable or USB. Hardware with IO interface can be integrated via an IO module, the IO interfaces of the robot controller or via a programmable logic controller (PLC).

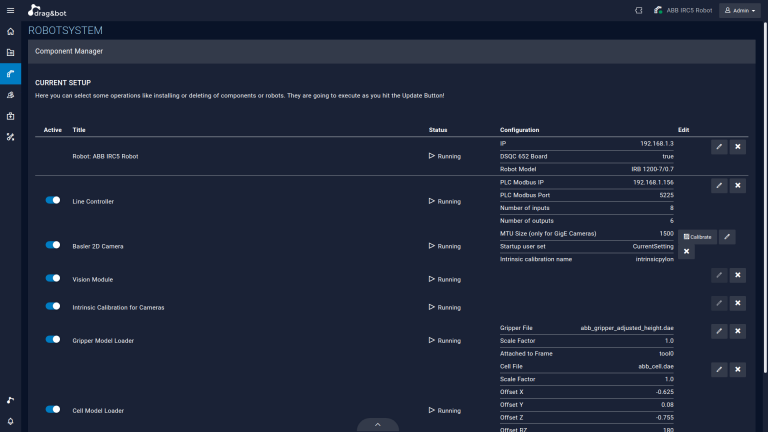

Step 2: Robot System Configuration

The user configures the connected hardware in the component manager. The installation of the corresponding drivers for the hardware takes place fully automatically in the background. The desired function blocks for the corresponding hardware can then be loaded. For certain hardware, a configuration for communication with drag&bot is also necessary.

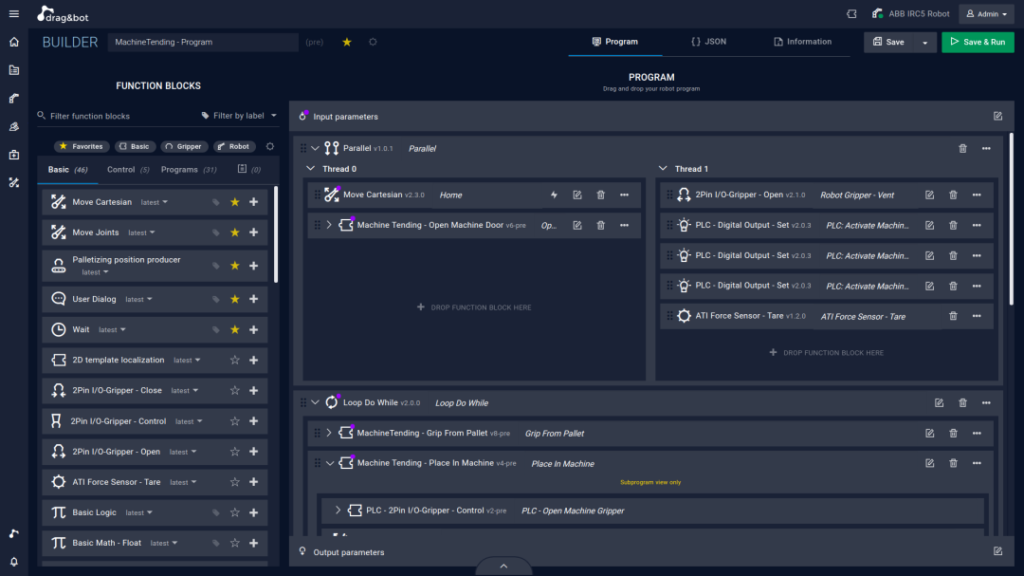

Step 3: Create a Robot Program

In drag&bot Builder, applications can be created from predefined function blocks using drag and drop. drag&bot already contains all function blocks required for common robot applications, e.g:

- Move robot

- Open and close gripper

- Set and read I/Os

- Palletizing

- Loops, branches, parallel design

- Wait, cancel program, …

Step 4: Parameterise Blocks

Wizards are graphical operating and input aids. They help to configure the necessary settings for some function blocks via a graphical user interface. Users can thus adapt function blocks to the specific requirements of their application without expert knowledge. The following wizards are part of drag&bot CORE:

- Move robot and save positions

- Creating robot paths from individual positions

- Define the grid of a magazine for parts removal/storage

- Set finger position, closing force and closing speed of grippers

Additional wizards can be easily integrated into drag&bot if required

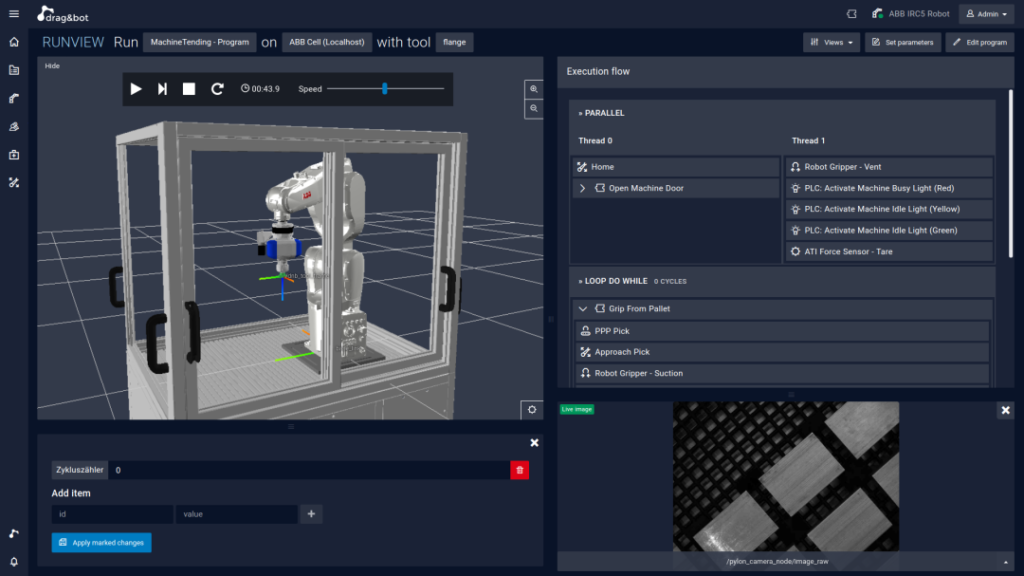

Step 5: Execute Robot Program

Applications created in the Run-View can be tried out immediately. The robot speed can be infinitely adjusted. During execution, the user receives information on where he is in the program at the moment. If “Stop” is pressed, the robot stops immediately. One-click takes the user back to the Builder, where the application can be expanded and optimized.