Evocon

All-in-one OEE system

Evocon is a leading provider of production monitoring and shop floor management solutions. Their real-time data collection and analysis tools enable manufacturing companies to enhance productivity, streamline operations, and make data-driven decisions for continuous improvement. With seamless integration of hardware devices and an intuitive software platform, Evocon empowers businesses to monitor key performance indicators (KPIs) and gain actionable insights.

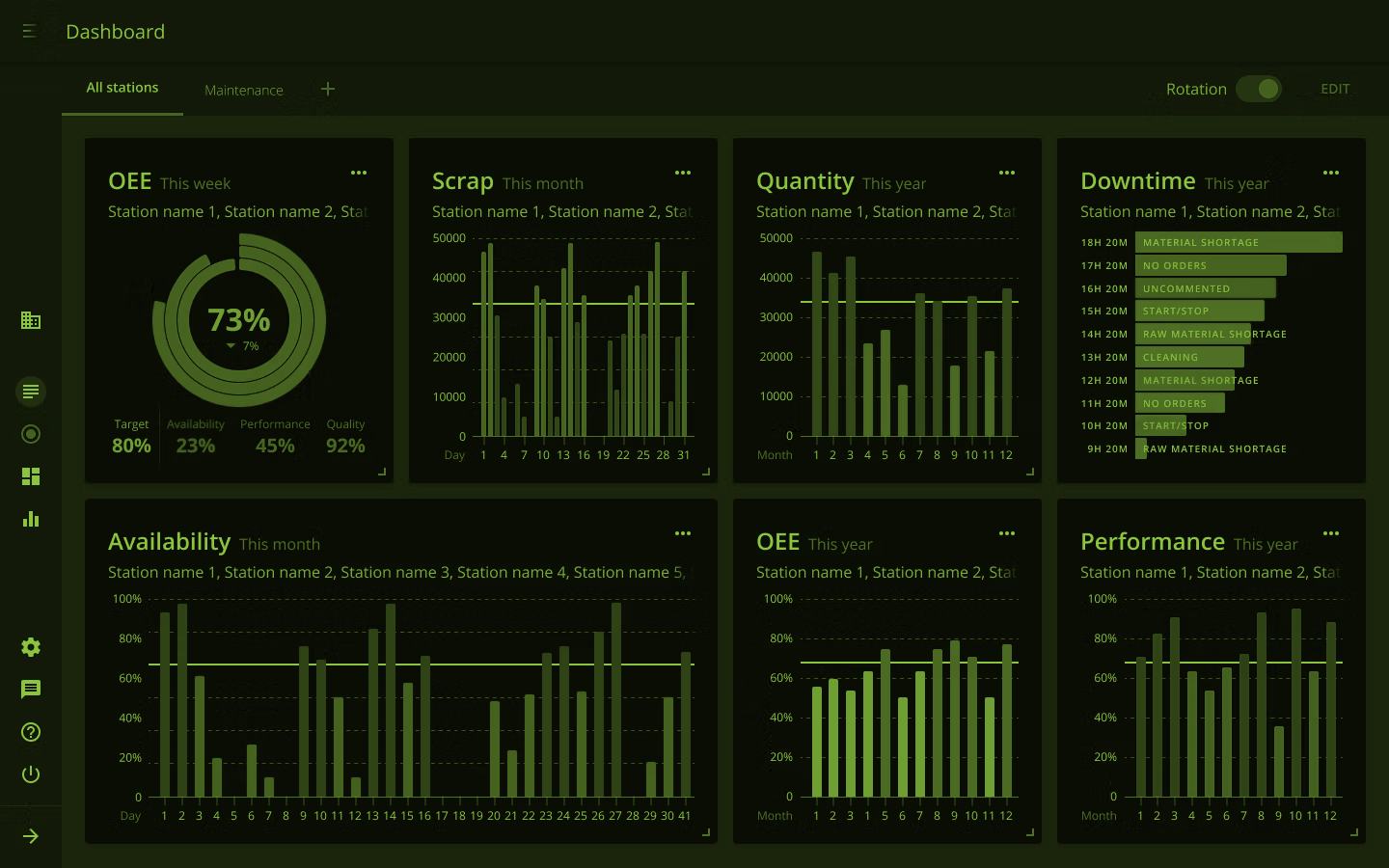

Information availability

Evocon is designed with information availability in mind. Get a complete understanding of your system performance in just a glance using the intuitive web application dashboard. There are no third party software requirements – Evocon uses a simple web application to manage your entire system.

Complete overview

With Factory Overview you make the status of all your machines visible to everyone. This gives your team the transparency they need to manage the factory in real-time and allows them to quickly react to any issues. No more unpleasant surprises.

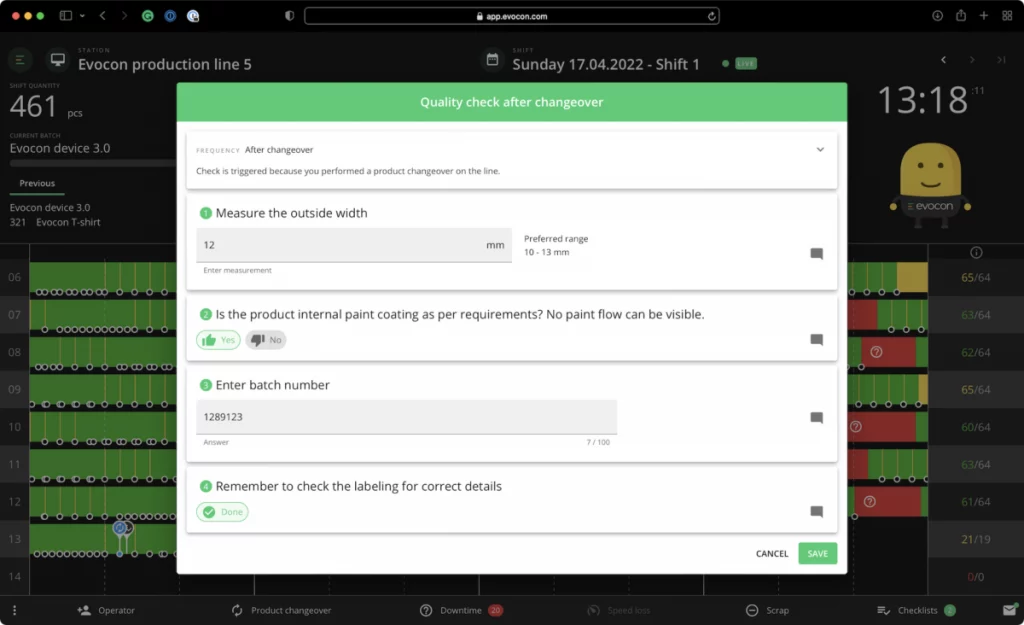

Advanced quality checking

With Checklists, you can digitize and automate all of your recurring quality and maintenance checks. By utilizing real-time data from machines you enable operators to do relevant checks and tasks at the right time, resulting in the reduction of waste and improvement in quality.

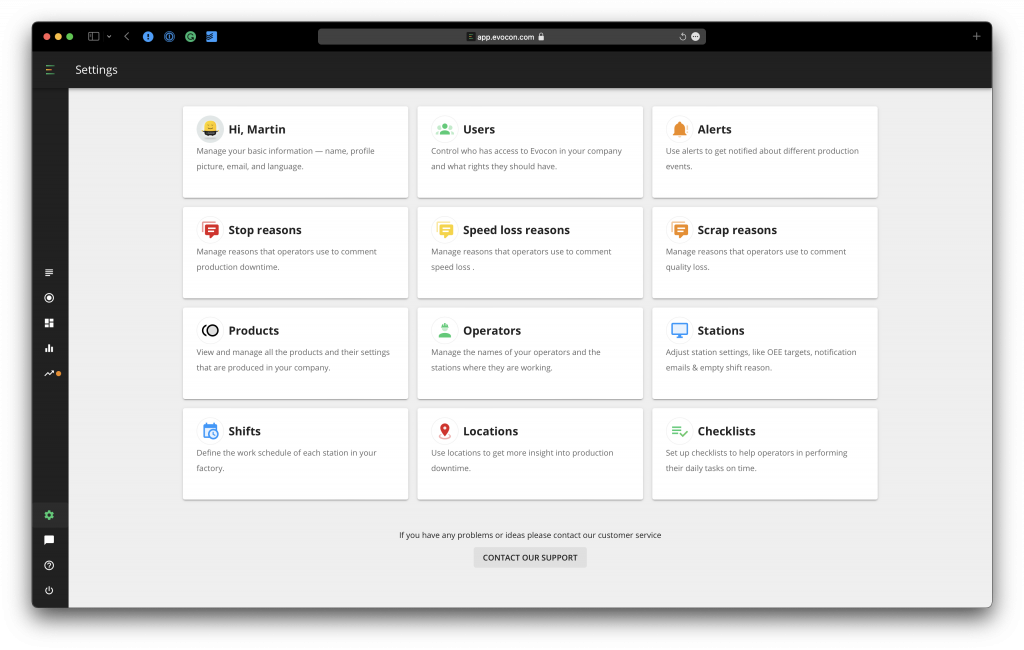

Highly configurable

Customise your OEE system with extensive settings provided by Evocon. Manage your products, shifts, users and alarms through an intuitive web interface. Create custom stop reasons, waste management schemes and user permissions entirely from the settings dashboard of an administrator account.

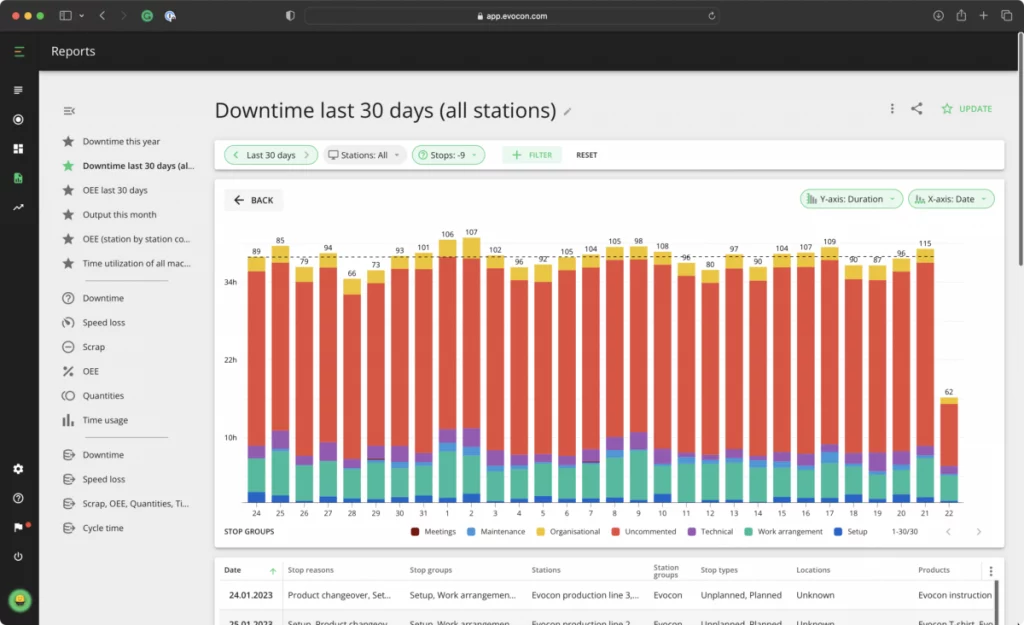

Track and analyse machine downtime

Evocon offers user-friendly tools to track and analyse machine downtime, helping teams reach goals and boost productivity. Features include automated data collection, real-time tracking, historical analysis, and root-cause analysis so you can eliminate unplanned downtime.

Engage everyone with unlimited uses

The more people you empower with accurate information, the better your results. With Evocon unlimited users feature you can invite everyone in your company to participate in the process of monitoring and improving.

Production planning based on actual data

Most manufacturers have a production plan, but how many consistently meet it? With Evocon monitoring your production, you’ll always know how your assets are utilized. With this knowledge comes an achievable schedule and a plan.

Cross-factory benchmarking globally

This standardization of OEE (Overall Equipment Effectiveness) tracking helps you benchmark differences between countries, regions, and factories more accurately than ever before. Leading to increased awareness, expertise, and sharing of best practices on a global level.

Want to learn more?

Get in touch today to see how an Evocon system can benefit your production line and help improve waste management.